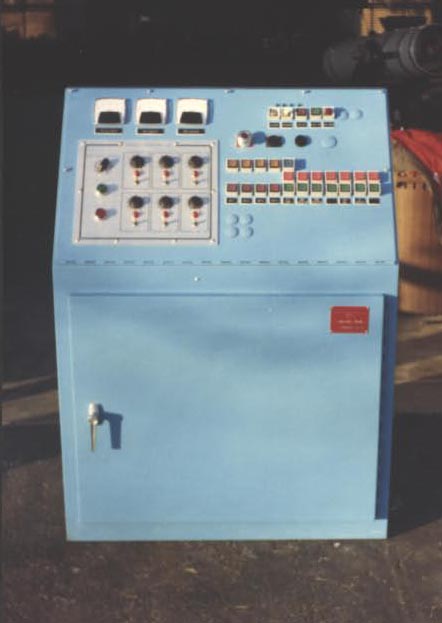

Automation can mean many things. But in its most basic form it points to a control of some sort that converts a dumb machine group into a functioning machine group that works in harmony to, generally, make things. This usually means a local control that is used to start, run, and monitor a conveyor or assembly line. It can range from a simple motor starter with a photo eye to keep stuff from running off the end, to sophisticated systems with plant integration and local work station instructions based on the product being worked on at each station.

We often get asked if we will do something as simple as a push button station. The answer is yes. For 35 years, we have been a full service control stopping point for design / build projects. We work with our clients to fit a cost effective solution to a need. If the project you have in mind is not worth the cost, we will tell you and normally give you an alternative to get the job done a different way at a better price.

In some cases,the solution isn’t electrical. We will also design and build mechanical as well as fluid logic systems. As one client put it a number of years ago, while we were doing a system going into a Class 1: Division 1; Group A location – no one has ever been pneumaticuted or air-sparked.

For more information contact us at Automation@Elogic-US.com or go to our contact information